| Bucket Capacity: 1.8m³ |

| Working Hours: ≥1100hours |

| Year: 2022 |

| Brand: Caterpillar |

| Shipping: Bulk cargo / Container/Flat Rack |

Original Caterpillar CAT 336 D Used Excavator in Backhoe Crawler Excavator

Why Choose Us

We have a strong mechanical team to ensure that all machines are well maintained, of high quality, and

100% original.

Spare parts are available, the most suitable for your machine.

We offer almost all types of second-hand construction machinery in good condition and at low prices.

Product Introduction

| Bucket Capacity: 1.8m³ |

| Working Hours: ≥1100hours |

| Year: 2022 |

| Brand: Caterpillar |

| Shipping: Bulk cargo / Container/Flat Rack |

Comprehensive description and product features of Caterpillar 336DL hydraulic excavator:

1. Basic parameters

Model positioning: 30-40 ton large crawler hydraulic excavator, belonging to Caterpillar D series products, mainly for mining and heavy-duty operation scenarios.

Operation weight: standard configuration is about 35,020 kg.

Bucket capacity: standard 1.5 m³ (rock bucket) or optional 1.64-2.87 m³ (standard bucket), to meet different working conditions.

Engine: Equipped with Cat® C9 ACERT diesel engine, rated power 208 kW, meets Tier 2/Euro II emission standards, and has high altitude adaptability (up to 2300 meters).

Fuel tank capacity: 620 L, supports long-term continuous operation.

2. Core performance features

Digging force and efficiency

The bucket digging force is 222 kN, and the digging force of the dipper arm is about 200 kN. With a large bucket capacity bucket, the loading efficiency is significantly higher than that of competitors of the same level (such as Komatsu PC360 and Hitachi ZX330).

The hydraulic system adopts intelligent technology (such as boom regeneration circuit and heavy load lifting mode) to optimize energy utilization, improve operation speed and precise controllability.

According to actual measurements by users, it only takes 15 buckets to load a 40 cubic meter dump truck, and the swing brake stroke is only 6-7 cm, with leading control accuracy.

Stability and durability

The chassis system is equipped with grease-lubricated tracks as standard, and the widened design (optional LN or L type) enhances stability in complex terrain, and the X-shaped box-section body has strong anti-twisting ability.

Key structural parts (such as booms and dipper arms) are made of high-strength steel, which are reliable in mining operations. Users report that there is no record of major repairs during continuous high-load operations.

Fuel economy

The average fuel consumption in economy mode (E mode) is 28-33 L/h. The fuel consumption in power mode is higher but suitable for extreme working conditions.

Automatic engine speed control technology reduces fuel consumption under light load conditions, and the hydraulic hybrid system recovers swing braking energy to further reduce fuel consumption.

3. Cab and operating experience

Comfort design

The cab is mounted with viscous rubber shock absorbers and equipped with a suspended seat (adjustable height, tilt and heating function), which significantly reduces vibration and noise.

The high-resolution LCD monitor supports multi-language display and integrates the rearview camera screen to improve operating safety.

The pressurized cab is equipped with automatic air conditioning as standard, and a falling object protection system (FOGS) and impact-resistant glass are optional.

Human-machine interaction

The electric control joystick supports personalized adjustment, is ergonomic, and reduces operator fatigue.

Optional Cat intelligence systems (such as Product Link) can achieve remote monitoring and fault warning.

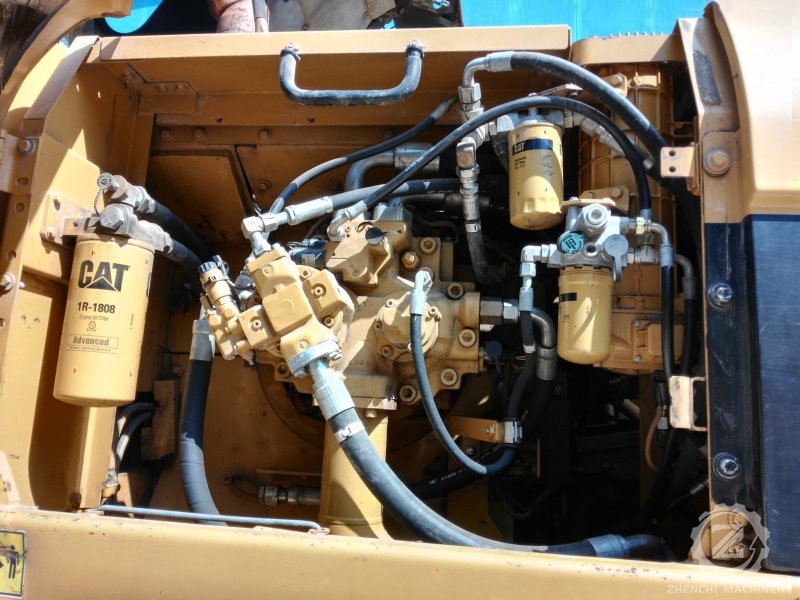

4. Maintenance and reliability

Convenient maintenance

Centralized filters (fuel, hydraulic oil) and ground inspection points reduce downtime.

Extended maintenance cycle (such as air filter replacement cycle up to 1000 hours), reducing operating costs.

Durability feedback

User cases show that continuous operation in mining environment exceeds 18,000 hours without major repairs, only routine maintenance is required.

Original accessories (such as sealed and lubricated rollers and guide wheels) have a long life, but the price is relatively high.

5. Application scenarios and adaptability

Typical uses: hard rock mining, mine loading, large earthwork and hoisting operations.

Multi-tool compatibility: support hydraulic hammers, grabs, crushers and other accessories through quick-change connectors to expand functions.

Special configuration: optional heavy-duty (HD) or large bucket (ME) front linkage to meet different excavation depths and strength requirements.

6. User evaluation and shortcomings

Advantages summary:

Strong power, precise control, outstanding mining operation efficiency.

Durable structure, low failure rate, and controllable long-term use costs.

Main disadvantages:

Accessories are expensive, and some designs (such as air conditioning inlet baffles) are fragile.

Early models have a slight oil burning phenomenon and need to be replenished regularly.

related products

Leave Us A Message